|

[ Home ] [ Up ]

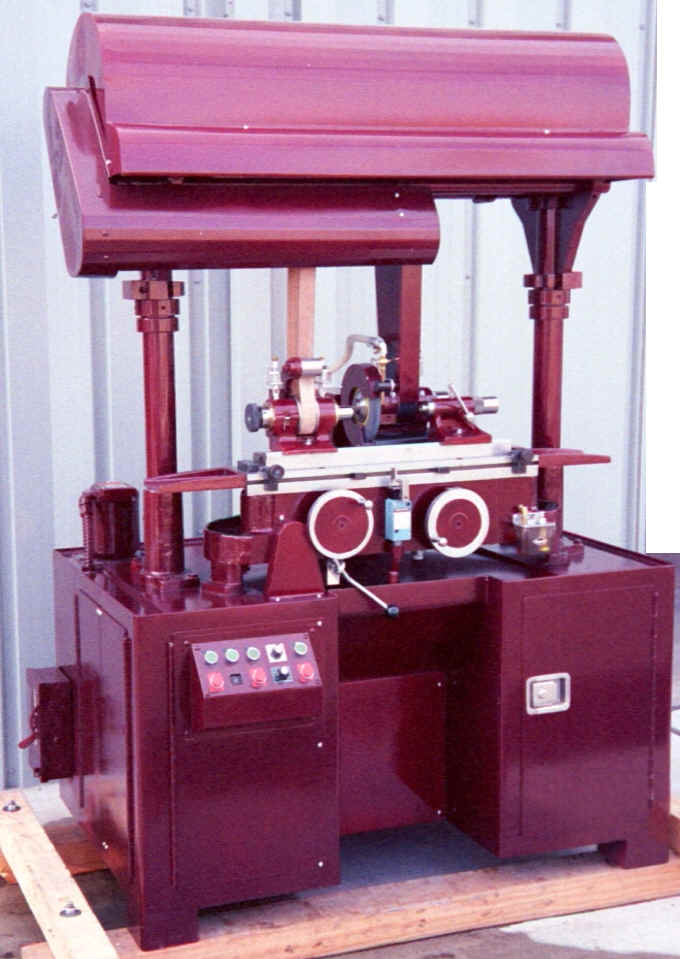

608 Plain Auto Table

Model 1018 Uni. on 90" cabinet

Flow

Control Grinder

| |

Index

POOR FINISH

OUT-OF-ROUNDNESS

WHEEL JUMPING

WHEELHEAD RUNNING

HOT

SPIRALING

Electrical

CLG's

web Contents

- POOR FINISH

-

When difficulty arise with

finish

-

(fishtails, chatter or just generally

poor)

-

check

for

- (1) Dirty

coolant (fishtails)

- (2) Accumulation of grinding residue around wheel guard

- (3) Wrong

Wheel

- (4) Coolant not rich enough or bad

- (5) Loose

Spindle

- (6) Diamond Dull or above center line

- (6) Dressing

Wheel too fast (cutting a thread in wheel)

-

[Top]

-

- OUT-OF-ROUNDNESS

-

when

difficulty arise with roundness

- (bigger

in center and or ends, cam or diameter off center)

check

for

- (1) Wheel

Spindle loose in bearings

- (2) Wheel loose on spindle

- (3)

Diamond Dull or moved above center in holder

- (4) The Universal Headstock is swiveled out of line with tail

- (5) On

older machines,. Alignment is off between head and tail

- (6) Centers in work not true or different than centers in machine

- (7)

Centers in machine bad

-

[Top]

- WHEEL JUMPING

-

when

difficulty arise with Wheel jumping

- (Wheelhead

creeping in on work unexpectedly)

Check

for

- (1) Gib

too tight

- (2) No oil on wheel ways (Move in-feed back and forth in oil

- (3) On

Universal Models, the rack tightened, but not parallel

- to slides and binding on one end

- (4) Worm too tight to Worm Gear. Loosen eccentric and turn to

-

correct. Refer to maintenance sheet

- (5) Plain

Grinders in-feed gears dry, clean and grease

-

[Top]

-

- WHEELHEAD RUNNING

HOT

-

when

difficulty arise with Wheel running to hot

- (wheelhead

temperature running above 180 degrees)

Check

for

-

- (1) Wheel

Spindle too tight

- (2) Belt tension to tight. Refer to maintenance sheet

-

-

- SPIRALING

-

when

difficulty arise with Wheel running to hot

- (barber

spiral or helical spiraling on work)

Check

for a combination of

-

- (1) Wheel

Spindle loose in bearings

- (2) Wheel loose on spindle

- (3) Wrong

wheel (Wheel loading Bond of wheel to hard try softer)

- (4)

Diamond Dull or moved above center in holder

- (5) The Universal Headstock is swiveled out of line with tail

- (6) On

older machines,. Alignment is off between head and tail

- (7) Centers in work not true or different than centers in machine

- (8)

Centers in machine bad

-

[Top]

Electrical

when

difficulty arise with any of the following

components

listed below

replacement

is recommended

- (1) Any

contacts, rectifers, generators, reostates,

- (2) Wheel loose on spindle

- (3) Wrong

wheel (Wheel loading Bond of wheel to hard try softer)

- (4)

Diamond Dull or moved above center in holder

- (5) The Universal Headstock is swiveled out of line with tail

- (6) On

older machines,. Alignment is off between head and tail

- (7) Centers in work not true or different than centers in machine

- (8)

Centers in machine bad

-

[Top]

-

|