|

[ Home ] [ Wheelhead ] [ Workhead ] [ Tailstock ] [ Tables ] [ Misc. Parts ]

608 Plain Auto Table

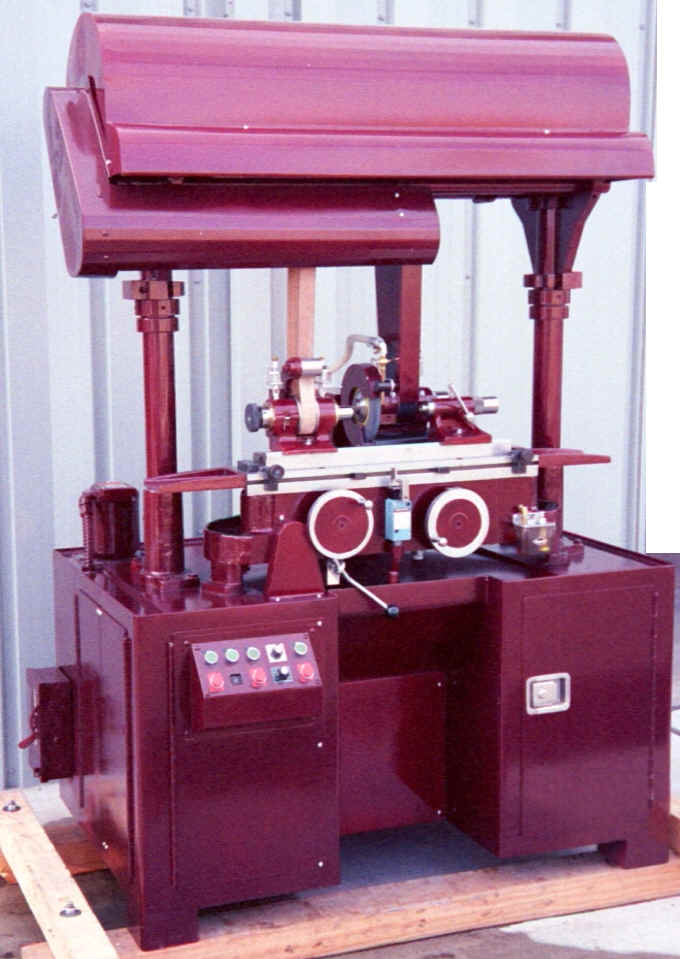

Model 1018 Uni. on 90" cabinet

Flow

Control Grinder

| |

- Wheelhead

-

Spindle is high speed steel, double taper design.

Hardened and ground and fit by hand scraping to 660 bronze, double

taper bearings. Spindle end-play is easily set by the adjusting

nut and gap measured with a dial indicator set against Spindle

face. Spindle operation is accomplished by hydraulic pressure

created by a thin film of oil applied by capillary action to the

spindle and bearing surfaces. The spindle therefore floats on

the oil-film like a car hydroplaning on a wet road. Wheelhead is

liquid cooled. Running temperature is typically 180

degrees. The Wheelhead Page

contains a list of New Wheelheads with their part numbers.

Wheelhead parts

lists for any current head can be found on the Page for a specific

Wheelhead.

- Workhead

-

Workhead/Headstock spindle is designed to accept 3c, 4c or 5c

collets, depending on machine model. Nose of spindle is ground

to a one degree taper, easily accepting the Dead Center Driver or any

number of part chucking methods, including 3 jaw, 4 jaw, 6 jaw, magnetic

chucks, face plates or fixtures. Bearing design is same as

Wheelhead assuring smooth and vibration dampening operation.

Attention to detail is assured when Headstock is paired and bored to

tail. After assembly, alignment is checked and hand scraped to

meet ridged requirements, so critical to the roundness of ground

parts. Equipped with Centering collets and carbide tipped

centers provides trouble free accuracy during dead center grinding

applications. The Workhead Page

contains a list of New Workheads with their part numbers.

Workhead parts

lists for any current Workhead can be found on the Page for a specific

Workhead.

- Tailstock

-

Is of plain design. Spindle is extra long hardened and

ground tool Steel. Closely fitted to bore of Tail giving

tremendous rigidity without loss of sensitivity to spindle. Dust

cap holds spring and can be adjusted for tension. Hole through

spindle for easy center knockout. The

Tailstock Page contains a list of New Tailstocks with their part

numbers. Parts lists for any current Tail can be found on the

Page for a specific Tail.

- Tables

-

Main Table is of V and Flat design and mated to the heavy base

casting. Stress is relieved by aging. Hand scraping

assures the precision needed to maintain accuracy down the length of a

long part. Scraper hills and valleys leave thousands of oil reservoirs

throughout the mating parts which translate to smooth vibration

dampening service. The Compensating table mounts atop the Main

Table is also of V and Flat design, swiveling six degrees either side

of center. The Table Page contains a

list of New Tables with their part numbers. Parts lists for any

current Table or Table Gearing can be found on the Page for a

specific Table.

- Misc.

Parts

-

The Misc. Parts Page contains a list of

New Parts with their part numbers which are Listed under a titled

aspect of the machine (where the part is installed on the machine)

like In-feed, Counter Shaft etc..., or

its industrial classification. (example: bearings, electrical etc...).

-

|